Michigan researchers have built a prototype of a new auto motor that does away with pistons, crankshafts and valves, replacing the old internal combustion engine with a disc-shaped shock wave generator. It could slash the weight of hybrid cars and reduce auto emissions by 90 percent. This is an enormous improvement compared to conventional vehicles, where about 85 percent of fuel simply blows out the back end.

The new generator is about the size of a saucepot, and would replace the 1,000-pound power train in most cars — no transmission, cooling system, emissions regulation or fluids needed.

The generator would also use about 60 percent of fuel for propulsion, which is a dramatic improvement over typical car engines, which use only 15 percent of fuel for forward movement. The system could also make cars 20 percent lighter, improving fuel economy even more.

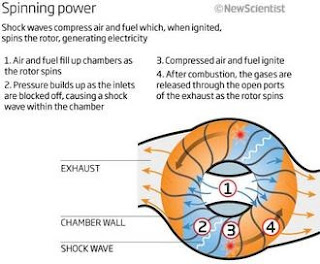

The keyword for the research team is shock. Their generator’s heart is a rotor that contains wavy radial channels. This construction allows for a much better exploitation of energy. After ignition, an air-fuel mixture enters the chambers of the generator. Due to the rotating model, the outlets and subsequently the inlets, too, are blocked, so the mixture can’t escape as it would in other engines. The resulting high pressure induces shock waves that rip through the car, and keep the engine roaring. Compression, temperature, density – everything is used in a more sustainable way, while pistons, camshaft and valves become superfluous.

The "shock wave" prototype, a project made possible with funding from the US Department of Energy, can replace nearly 1,000 lbs. of engine, transmission, cooling system, emissions, and fluids. Companies could consider building vehicles that are lighter, smaller, and—greener. And with an overall larger awareness from the population to save energy rising, the demand is definitely there. The team in Michigan hopes to have an even larger 25-kilowatt prototype by the end of this year.